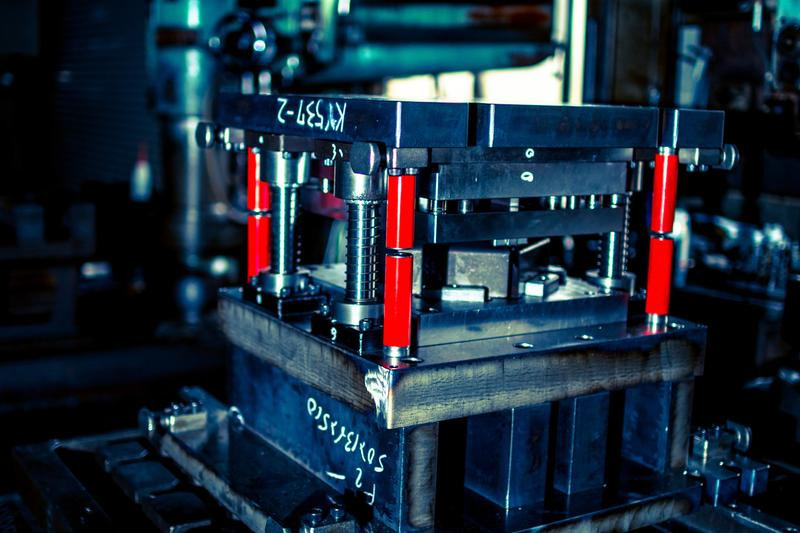

Complex Furniture Hardware Stamping Technology: Preventing Cracking and Wrinkling in Custom Metal Fittings

Release time:

2025-05-10

1. Optimizing Challenging Areas in Custom Metal Fittings

Corner Treatment Methods:

- Implement corner relief designs to distribute stress and prevent concentration in critical areas of sofa leg hardware.

- Add local reinforcement structures to enhance material stability in high-stress zones of custom metal components.

Multidirectional Drawing Technology:

- For asymmetrical furniture hardware parts, employ sequential drawing from multiple directions to balance material flow and prevent wrinkling.

- Use segmented blank holders to provide differentiated pressure distribution across varying part geometries.

2. Process Simulation and Validation for Precision Metal Stamping

FEA-Based Process Optimization:

- Conduct finite element simulation to identify potential failure points before actual metal stamping production.

- Validate optimal blank-holding force curves and draw bead configurations through virtual testing.

Material Flow Analysis:

- Analyze thickness distribution and strain patterns to predict and prevent thinning and cracking in complex hardware designs.

- Implement strain-based process control to maintain consistent quality in high-volume production runs.

3. Quality Inspection and Process Monitoring

In-line Monitoring Systems:

- Deploy force sensors and vision systems to detect abnormal conditions during metal stamping operations.

- Establish real-time feedback loops to adjust process parameters automatically based on measured outcomes.

Statistical Process Control:

- Track key quality metrics to identify trends and prevent systematic defects in custom hardware production.

- Implement preventive maintenance schedules based on tool wear predictions and material variability analysis.

By integrating these comprehensive approaches into furniture hardware manufacturing processes, producers can significantly reduce defects while enhancing the precision and durability of custom metal fittings and sofa leg hardware components, ultimately delivering superior quality and cost efficiency.

Related News